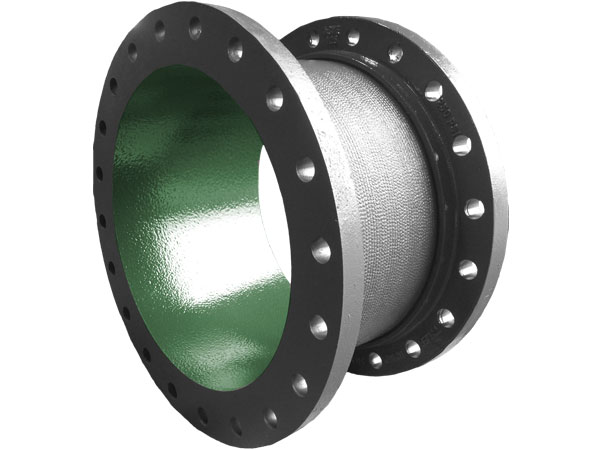

C&B Piping CBGL911 Porcelain Glass Lining

C&B Piping manufactures CBGL911 Porcelain Glass Lining for ductile iron piping systems. Glass lining is typically used to prevent clogging build up or wear for sewage service lines which contain solids content. Glass lining provides a superior non stick surface.

C&B Piping Field Repair Kit for CBGL911 Glass Lining

C&B Piping stocks and offers repair kits for CBGL911 Glass Lining. These kits are needed to repair field cut pipe and touch up for fittings and fabrications.

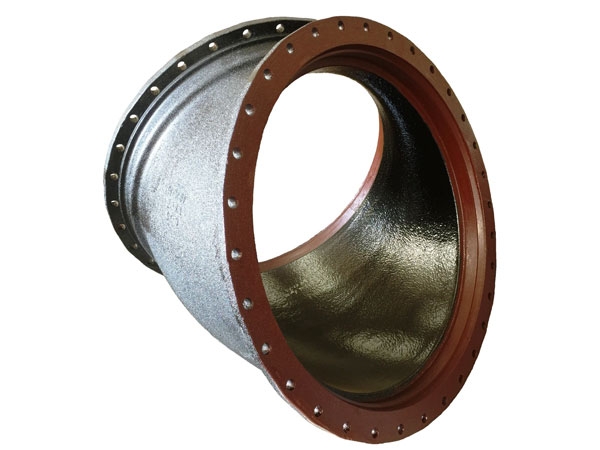

Induron Protecto 401 Ceramic Epoxy Lining

C&B Piping is a licensed applicator of Protecto 401 Ceramic Epoxy Lining for ductile iron pipe, fittings, and fabrications. Protecto 401 is the industry standard for protection of ductile iron piping sewer lines where corrosion protection is needed. Since 1981, literally thousands of miles of ductile iron sewer pipe have been lined with Protecto 401.

Induron Field Repair Kit for Protecto 401 Ceramic Epoxy

C&B Piping stocks and offers repair kits for Protecto 401 Ceramic Epoxy. These kits are needed to repair field cut pipe and touch up for fittings and fabrications.

Induron Ceramapure PL90 Epoxy Lining for NSF-61 Water

C&B Piping is a licensed applicator of Ceramapure PL90 Epoxy Lining for ductile iron pipe, fittings, and fabrications. Ceramapure PL90 is used primarily for water lining applications where cement lining is not desired. Ceramapure PL90 is NSF-61 approved. Ceramapure PL90 can also be used in wastewater applications. Ceramapure PL90 is also used as an superior alternative to Fusion Bonded Epoxy coatings on ductile iron pipe or fittings. Ceramapure™ PL90 meets or exceeds the compliance standards for AWWA C-210.

Induron Ceramawrap Epoxy Coating for ductile iron pipe

C&B offers Ceramawrap Epoxy Coating for exterior protection of ductile iron pipe and fittings in aggressive atmospheres and liquids. Ceramawrap contains ceramic quartz pigment and amine cured epoxy. It is ideal for aggressive sewage lift stations and saltwater protection for piping on bridges in ocean environments.

C&B Piping Arc Spray Zinc ISO 8179-1

C&B Piping provides Arc Spray Zinc application to ductile iron pipe, fittings, fab closures, and flanges. Our process complies with ISO 8179-1. Zinc is effective in providing cathodic protection to the surface of iron & steel which extends the surface life of the product.

Tnemec Perma-Glaze Series G435

C&B offers Tnemec Perma-Glaze Series G435 modified polyamine epoxy for protection on the exterior of ductile iron pipe.

For more information, please contact C&B Piping, LLC

Tnemec L140F Pota-Pox Plus

C&B offers Tnemec L140F Pota-Pox Plus as a shop coat when required. L140F is a polyamidoamine epoxy and meets the NSF 61 drinking water requirements.

For more information, please contact C&B Piping, LLC

Tnemec Tneme-Zinc 90-98 / Asphalt Topcoat – ISO 8179-2

C&B offers Tnemec Tneme-Zinc 90-98 with an Asphalt Topcoat for specifications requiring Zinc coating protection per ISO 8179-2.

For more information, please contact C&B Piping, Inc.